I should preface that my primary vacuum tube experience is related to trying to fix the 1920s built-in wall radio made of redwood in a house my family rented when I was in elementary school.

Readers, I never fixed that radio.

[The fourteenth in an ongoing series of my compiled explainers for my CHOOSE YOUR OWN RADIATION ADVENTURE quizzes. There’s never really a right answer but some might work out better under the constraints of the scenario. It’s like poetry, really.]

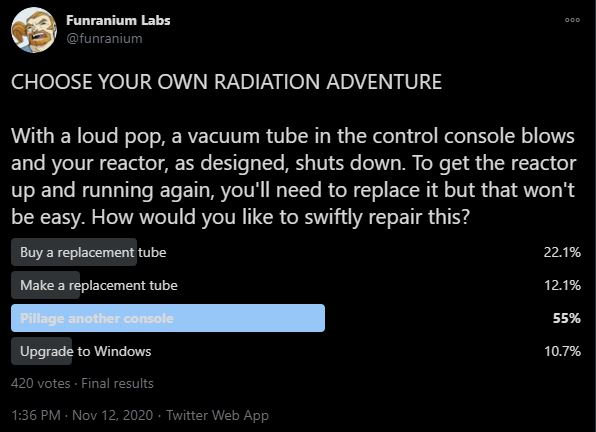

But wait you say [does math] if the average age is 40 years old, how can there be reactors older than NRC, the agency that licenses them? (NOTE: the NRC’s birthday is 19 January 1975, so it’s a Capricorn) It’s because the old reactors still have their original licenses from the Atomic Energy Commission. I tell you hwut, those dang ol’ AEC short form licenses are like six pages long for your reactor and reactor accessories. If you change NOTHING, you can keep renewing that original license. When you see a more current NRC license, you understand why people lock in. Preserving the configuration stated on your old AEC license is something that operators fight tooth and nail to retain because losing the grandfathered status is one whole hell of a lot of work. This is why blowing a tube is so critical. The most popular response, which was not one of the four choices, was to go get a spare from the supply cabinet of critical parts. And you can do that…for a while. Your predecessors certainly did that. But then they inconsiderately failed, or were unable, to restock for you. Because your predecessors have failed you, now you have the four choices as presented.

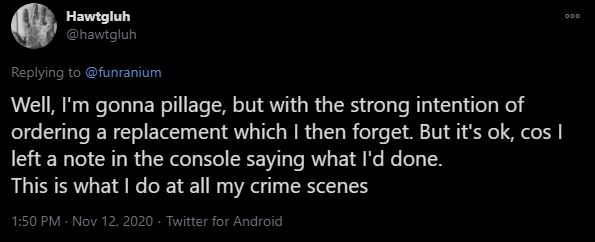

By far, the most popular choice was to pillage another tube from a less critical piece of equipment. If you’re lucky, that’s not a highly specialized tube and there’s one you can “reallocate”. Of course, you should make sure that yanking the tube from the other location isn’t also failsafe critical system which is why your reactor shut down in the first place. That tube was important enough that your reactor was designed to NOPE if it isn’t there to do its job. If you pillage, I want to make certain that you do what @hawtgluh said to do. Make a note in the operator’s log for what you did so that people know what other thing they also need to repair. Your successors may still curse your name but at least they know WHY.

And if you can’t find it, you can try to make a replacement tube. Making vacuum tubes isn’t as easy as you’d hope. I mean, it’s not terrible, but just like the tubes are rare these days so too are the skills and facilities to make them. So, if you depend on vacuum tubes I recommend you go make friends with glass blowers now. The more reasonable tinkering project is to make an adapter to use a different tube in that socket.

[BUZZER NOISE] Sorry, you just got a NRC violation notice.

Which brings us to Windows.

This is a wholesale replacement of your control systems with something more modern than an Atari 2600 that can run Windows, which means you’re submitting a new license application. It will be years until you turn the reactor back on. While many of you had UNCOMPLIMENTARY THINGS to say about Windows system integration, it has happened. The important thing to know is that critical equipment like this is very, VERY airgapped from the outside world. You can be a bit more confident under those circumstances.

The first time I walked in and asked what that flatscreen TV and single server blade in old, otherwise completely empty equipment rack was?

ANSWER: the replacement for the entire rest of the control room, in addition to all the data capture.

I said that was a neat upgrade but what redundancy did they have in the event of something like a water leak. There was a pained slow blink.

The next time I went back there were two blades in that rack. You know, for redundancy. [facepalm]

~fin~